by Eric Soifer, M.Arch 2019

Advisors: Chris Falliers and Thom Faulders

Stranded Strata: 3D-Printed Non-Efficient Architecture for Extreme Environments

Traditional construction techniques in extreme or remote environments necessitate massive human oversight and thus are impractical or impossible. Architecture and construction must embrace new technologies to build in these environments. This thesis asks: how can integrity emerge from imprecision in additive manufacturing? This project has been situated on Meridiani Planum slightly north of the Martian equator, an area rich in topographic features such as craters. Abundant local regolith is used as the building material and the site’s topography is the formwork.

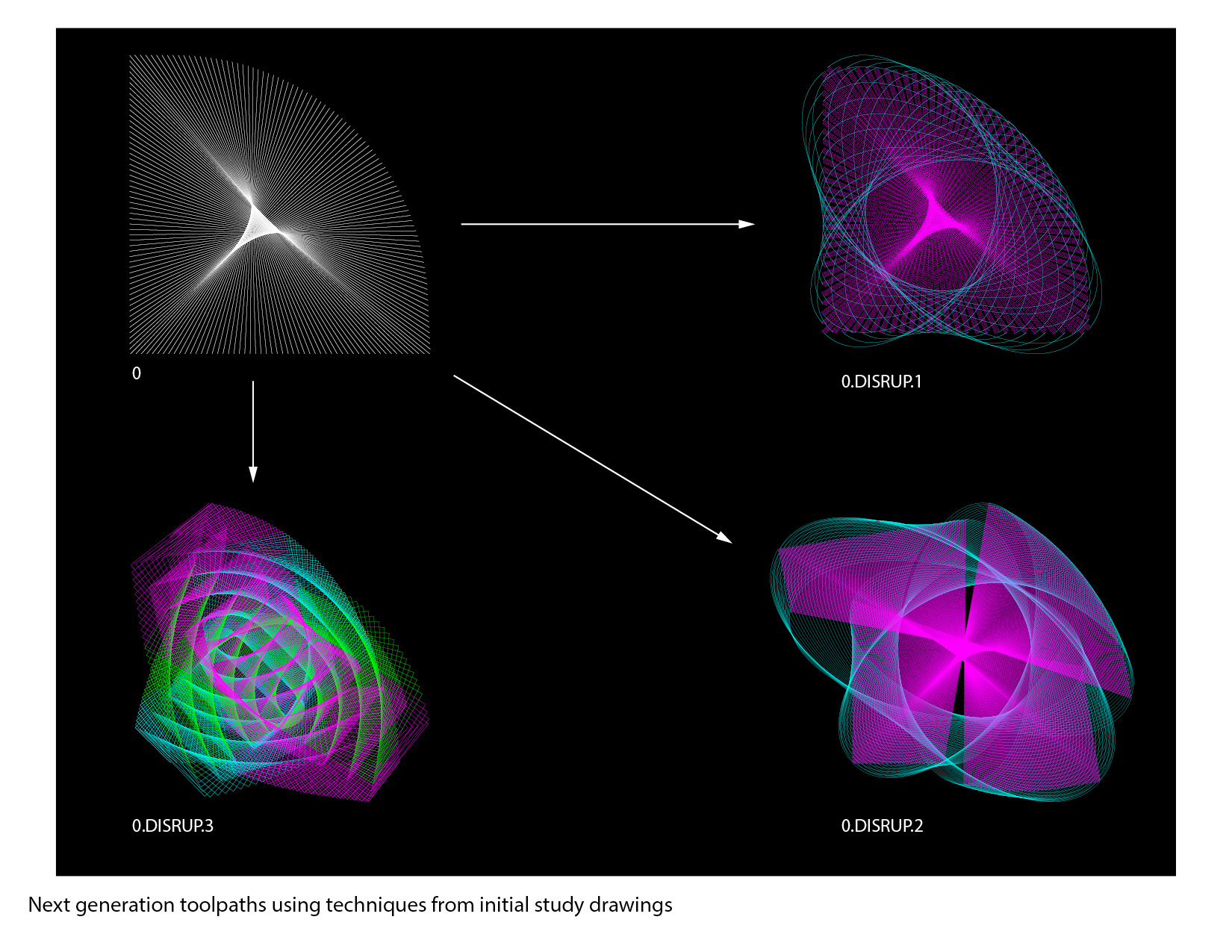

A Potterbot was used to simulate extrusion printing with local materials. A significant hurdle in this project was development a method to print over a surface that isn’t flat. The toolpath was designed in 2D then projected onto a 3D surface. Height was achieved by expanding the Z-axis. There are 2 generations of evolution on this project. The first generation was an exploration of material formation. A wide variety of toolpaths were used and the results analyzed for density, gradation, organization, and disturbance. Generation two took one toolpath from generation one that provided the most architectural opportunity and manipulated it to achieve a new set of criteria. Structural continuity, enclosure, spatial definition, detail/anomaly.

Once the clay prints were fired in the kiln they were rigid enough to experiment with their interaction with the topography, inspired by the variations in form that emerged during the printing process. Based on the analysis for a given criteria or potential program, the print was left in place, flipped over, or excavated around or beneath. Based on topography and orientation, prints that emerged from the same toolpath expressed many different architectural forms and features.

Mars is the most extreme example of an environment where this manufacturing process would have a lot of advantages over traditional methods. But all those advantages are also relevant on earth, such as the use of in-situ forms, local material, and less need for oversight.

Typical 3D printing relies on layer perfection. This project embraces the inevitability in layer failures by designing forms that rely on redundancy of line to create structure. This allows a reevaluation of the parameters of construction: time, efficiency, labor, and material. Imposing old construction techniques onto our new reality is a form of imperialism. This project breaks free of imported thinking by amplifying the local.